Why You Should Consider Thin Film Mounting End Clamps for Your Next Project

Release time:

2025-07-01

Source:

Why You Should Consider Thin Film Mounting End Clamps for Your Next Project

Table of Contents

- Introduction to Thin Film Mounting End Clamps

- Understanding Thin Film Mounting

- Advantages of Thin Film Mounting End Clamps

- Ideal Applications for Thin Film Mounting End Clamps

- Installation Guide for Thin Film Mounting End Clamps

- Maintenance Tips for Longevity

- Common Issues and Solutions

- Conclusion

- FAQs about Thin Film Mounting End Clamps

Introduction to Thin Film Mounting End Clamps

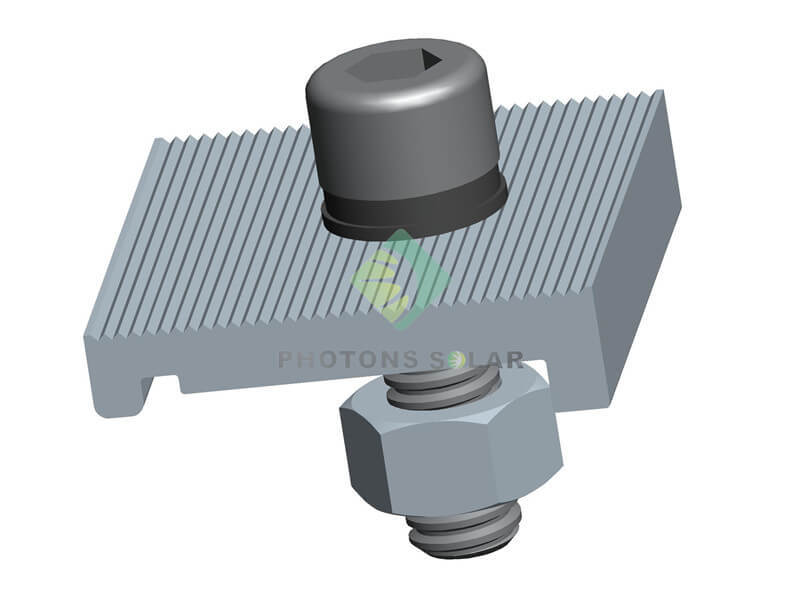

In the realm of construction, manufacturing, and renewable energy projects, the choice of hardware can significantly impact the overall performance and longevity of your work. **Thin film mounting end clamps** have emerged as a crucial component for securely fastening and supporting thin film solar panels, glass, or other delicate materials. These clamps are designed to enhance structural integrity while facilitating easy installation and maintenance. In this guide, we delve deep into why these clamps are an essential consideration for your next project.

Understanding Thin Film Mounting

Thin film mounting refers to the process of securing lightweight materials, such as solar panels or architectural glass, that require a supportive yet flexible attachment method. Unlike traditional mounting systems, thin film solutions prioritize ease of installation and reduce the risk of material damage during the mounting process. This innovative method is particularly beneficial in applications where weight and stability are paramount, allowing for a broader range of practical uses.

Advantages of Thin Film Mounting End Clamps

The use of thin film mounting end clamps offers several distinct advantages that can transform the success of your projects. Let’s explore these benefits in detail.

Durability and Reliability

**Durability** is a key factor when selecting mounting hardware. Thin film mounting end clamps are typically crafted from robust materials such as aluminum or stainless steel. These materials not only resist corrosion and rust but also withstand various environmental conditions, ensuring that they maintain performance over time. **Reliability** is paramount, especially in critical applications like solar energy systems, where any failure could lead to significant losses.

Cost-Effectiveness

When evaluating project costs, it's essential to consider the long-term benefits of thin film mounting end clamps. While the initial investment may be slightly higher than traditional clamps, the increased lifespan and reduced maintenance needs lead to overall cost savings. By minimizing the frequency of replacements and repairs, these clamps ultimately prove to be a more economically sound choice.

Versatility in Applications

Thin film mounting end clamps are incredibly versatile and can be employed in various settings, from residential solar panel installations to commercial glass facades. Their adjustable nature allows them to accommodate different thicknesses and materials, providing a customized solution for diverse project requirements. This adaptability makes them an invaluable asset in both new constructions and retrofitting projects.

Ideal Applications for Thin Film Mounting End Clamps

With their unique qualities, thin film mounting end clamps are suitable for numerous applications, including:

- **Solar Panel Installations:** Specifically designed for thin film solar technology, these clamps ensure panels are securely mounted without risk of damage.

- **Architectural Glass Projects:** The lightweight and flexible nature of these clamps makes them ideal for securing glass elements in modern architecture.

- **Industrial Applications:** These clamps can also be utilized in various industrial settings where lightweight materials need careful handling and support.

Installation Guide for Thin Film Mounting End Clamps

Proper installation is crucial for the effectiveness of thin film mounting end clamps. Here's a step-by-step guide to ensure you achieve optimal results:

1. **Plan Your Layout:** Start by determining the optimal placement for your clamps. This involves measuring the space and ensuring that the clamps will evenly distribute weight.

2. **Prepare the Surface:** Ensure that the mounting surface is clean and free of debris, which can impede the effectiveness of the clamps.

3. **Position the Clamps:** Place the clamps at designated points along the material. Make sure they are evenly spaced to provide balanced support.

4. **Secure the Clamps:** Use appropriate fasteners to secure the clamps in place. Be cautious not to overtighten, as this can lead to material damage.

5. **Final Checks:** After installation, conduct a thorough check to ensure that all clamps are properly secured and positioned.

Maintenance Tips for Longevity

To ensure the longevity of your thin film mounting end clamps, regular maintenance is essential:

- **Conduct Regular Inspections:** Periodically check for signs of wear or corrosion and address any issues promptly.

- **Clean the Clamps:** Use a gentle cleaning solution to keep the clamps free from dirt and debris, which can compromise their integrity.

- **Tighten Loose Fasteners:** Regularly check and tighten any loose fasteners to maintain secure connections.

Common Issues and Solutions

While thin film mounting end clamps are durable, certain issues may arise. Here are some common problems and their solutions:

- **Corrosion:** If you notice corrosion, replace the affected clamps with corrosion-resistant options to prevent further damage.

- **Loose Clamps:** Regular inspections can help catch loose clamps early. Ensure to tighten fasteners as needed.

- **Material Damage:** Always use clamps designed for the specific material to avoid damage during installation or regular use.

Conclusion

In conclusion, **thin film mounting end clamps** offer numerous advantages that can significantly enhance the efficiency and durability of your projects. Their robust construction, versatility, and cost-effectiveness make them an essential choice for a variety of applications. By investing in high-quality clamps and adhering to proper installation and maintenance practices, you can ensure the longevity and reliability of your work. As the industry continues to evolve, embracing innovative solutions such as thin film mounting end clamps will keep you ahead of the curve.

FAQs about Thin Film Mounting End Clamps

What are thin film mounting end clamps made of?

Thin film mounting end clamps are typically made from durable materials like aluminum or stainless steel to ensure resistance to corrosion and environmental challenges.

How do I install thin film mounting end clamps?

Installation involves planning the layout, cleaning the surface, positioning the clamps, securing them with appropriate fasteners, and conducting final checks for security.

Are thin film mounting end clamps suitable for all materials?

While they are versatile, it's essential to select clamps specifically designed for the material you're working with to avoid damage.

How often should I inspect my thin film mounting end clamps?

It's advisable to conduct inspections at least twice a year or more frequently in extreme weather conditions to ensure their effectiveness.

Can thin film mounting end clamps be reused?

Yes, as long as they are not damaged and are in good condition, thin film mounting end clamps can often be reused in future projects.

Thin film mounting end clamp

Related News

2025-07-01 12:20

Why You Should Consider Thin Film Mounting End Clamps for Your Next Project

Why You Should Consider Thin Film Mounting End Clamps for Your Next Project Table of Contents Introduction to Thin Film Mounting End Clamps Understanding Thin Film Mounting Advantages of Thin Film Mounting End Clamps Durability and Reliability Cost-Effectiveness Versatility in Applications Ideal Applications for Thin Film Mount

2025-06-28 11:40

Enhancing Outdoor Spaces: The Benefits of Solar Panel Covered Walkways

In recent years, the adoption of renewable energy solutions has become a focal point for both residential and commercial properties. One such innovative solution is the solar panel covered walkway, which not only enhances the aesthetic appeal of outdoor spaces but also provides significant environmental benefits. By harnessing solar energy, these walkways can contribute to energy savings and susta